MODELLING AND SIMULATION OF FLUID DYNAMICS (CFD)

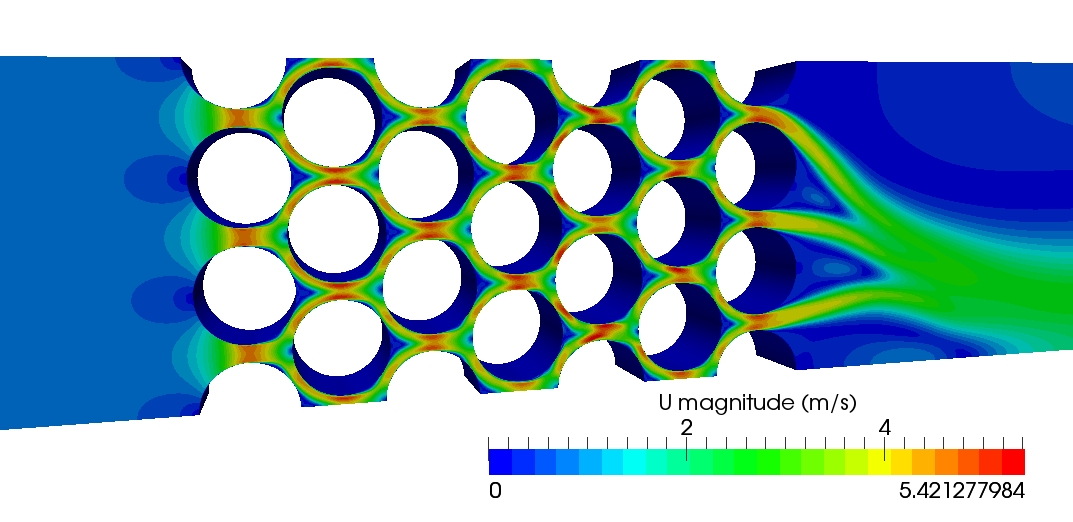

Computational Fluid Dynamics (CFD) experts group – scientists from Riga Technical university – brings together researchers from different scientific disciplines and helps solve gas and liquid flow problems by using advanced numerical methods. Thry:

- create simulation model from a 2D/3D drawing;

- perform parallel computing in the HPC cluster (supercomputer);

- study and interpret the results.

CFD computing tasks are among the most time-consuming ones, thus the possibility to use the HPC cluster allows getting results faster. We mainly work with open source software (OpenFoam, Paraview), although we also have certain experience in using commercial solutions like COMSOL Multiphysics.

The service is particularly aimed at innovative companies (SMEs, startups) and scientific institutes that want to improve their research and development processes. Computer simulation allows to understand the processes in a system better, as well as to predict and prevent problems even before the prototype or end product is made.

Service delivery time

Depending on the geometry, it can take several weeks to create the initial simulation model.

Simulation of a complete model in the supercomputer takes from several hours to a few days.

Information about prices is available here.

Practical usage

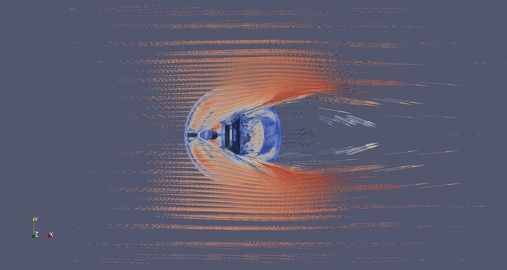

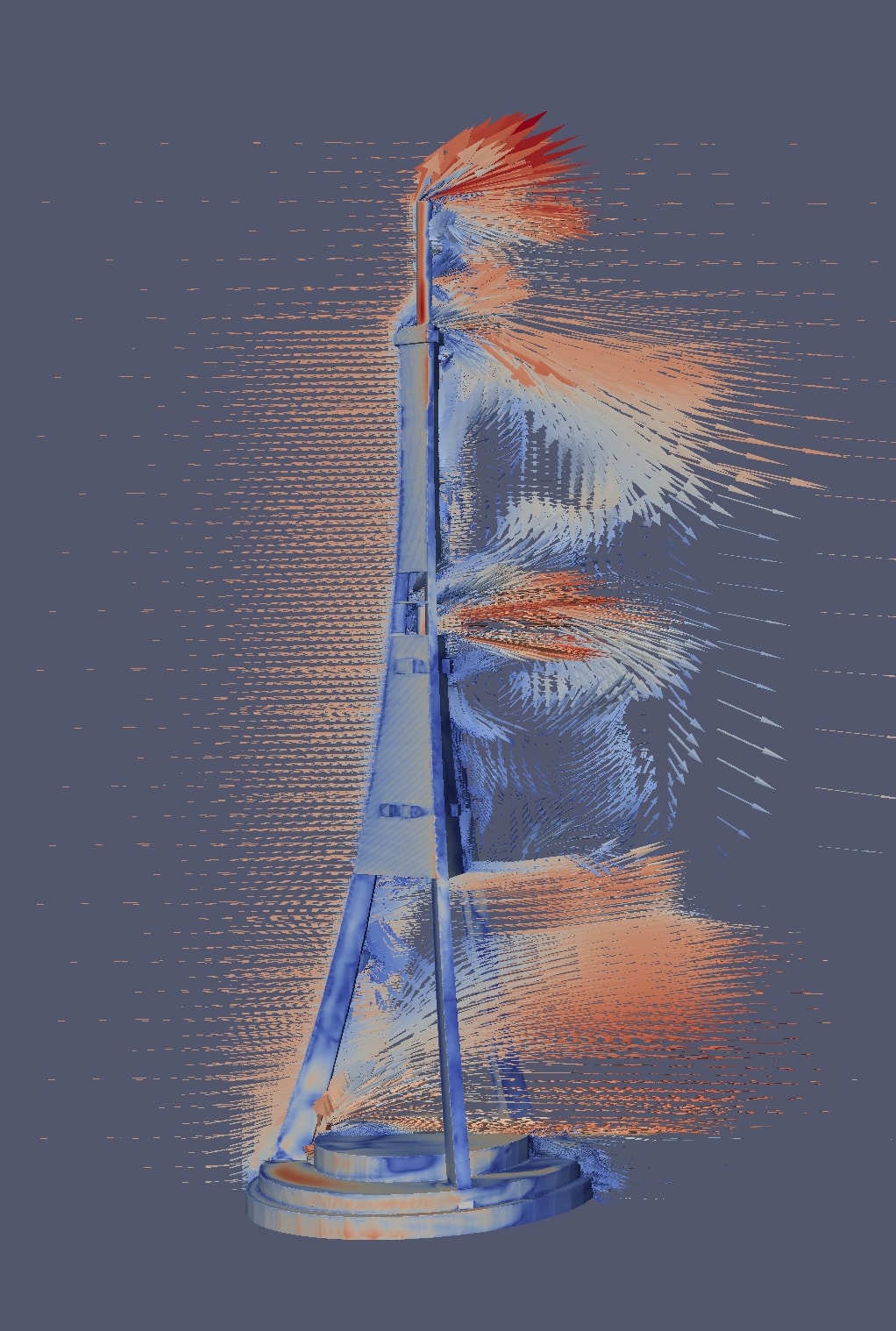

- To determine the impact caused by the planned changes to the façade of TV tower in Riga, Latvia, and the additional loads of wind, RTU scientists performed virtual wind tunnel simulations (CFD). They managed to establish the additional forces forming following the change of the aerodynamic parameters of the TV tower. The results were validated using the results of the physical wind tunnel experiment of the initial TV tower geometry. Overall, the results showed good correspondence with the experiment outcomes.

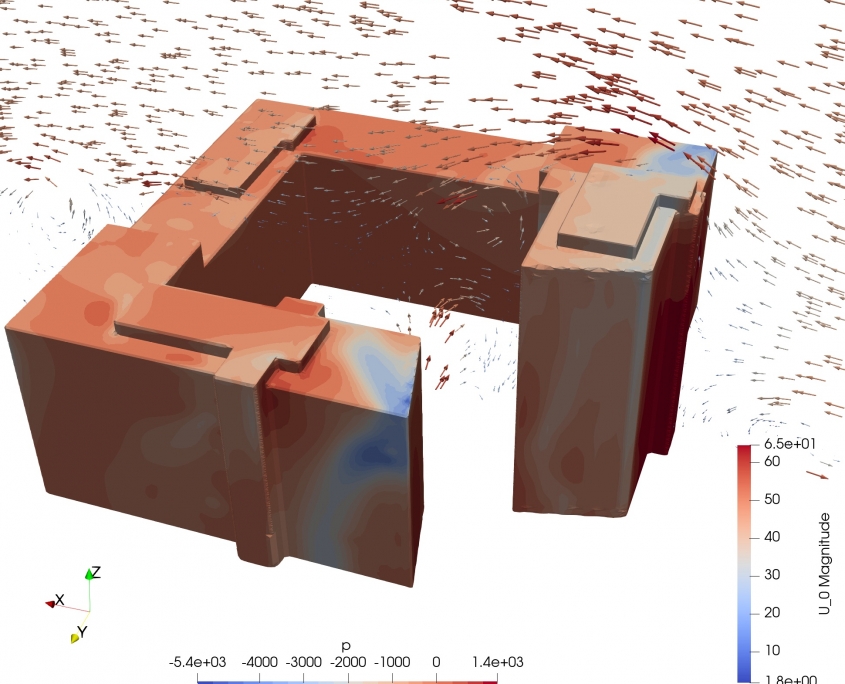

These results allowed to select the most suitable architectural solution for the TV tower facade.

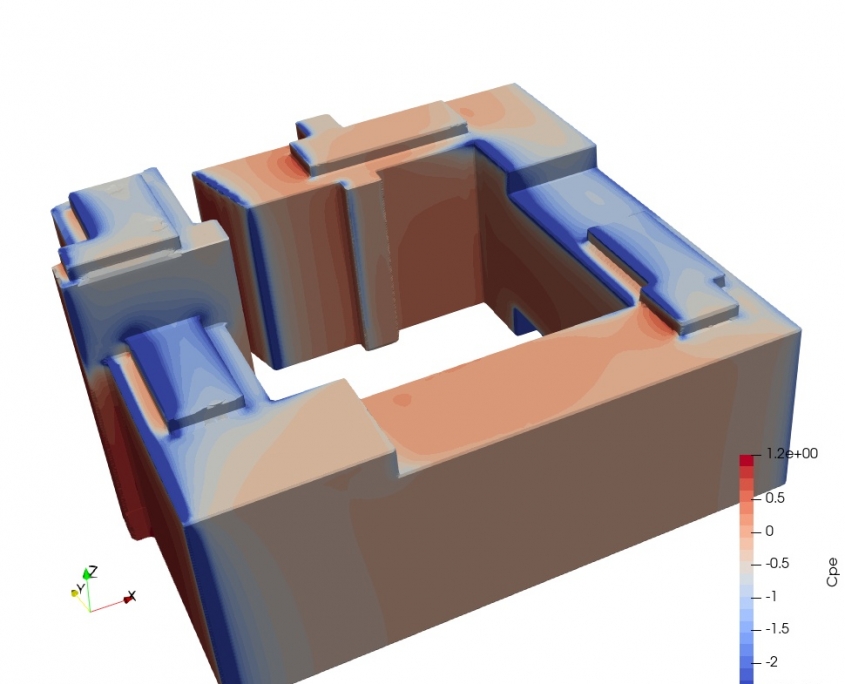

- In order to determine the required glass size of the building facades and to find the necessary wall mountings, the CFD simulation was carried out with the aim to determine leakage coefficients Cpe on the facades of the building’s inner courtyard. There was a virtual simulation of the wind tunnel and wind from all sides of the facade as well as diagonally. The result was a field with Cpe coefficients on the facade surface, which was further subdivided into several regions and the average Cpe coefficient was determined for each region. Such a calculation did not use a conservative approach that allowed a significant reduction in the cost of building facades.